...

-->Introduction

-->Importance of Proper Injection

-->Improving the Quality of Injection

-->Conclusion

...

QUALITY OF INTRAMUSCULAR INJECTION

By Marcelo PANIAGO, DVM, MSc, MBA. – Regional Market Manager - Poultry - Ceva Animal Health Asia Pacific

.

Introduction

The use of inactivated vaccines prior to the onset of the egg production is a very well established procedure in the poultry industry as it boosts the humoral immunity. This boosted immunity protects the own birds’ health during their lifespan and, in the case of breeders, it also improves the level and homogeneity of antibodies transferred to the progeny (maternally derived antibodies).

Vaccine manufacturers invest millions of euros to develop and produce high quality inactivated vaccines with well balanced emulsions and high concentration of antigens. However, these products have been injected in the same way producers were doing it more than half a century ago. Needless to say that this type of administration presents clear shortcomings and some of them as listed here below:

- Inactivated vaccines need to be individually injected through a very tiring procedure. Therefore, the quality of vaccination will be directly linked to the level of training and also level fatigue of the vaccination crew.

- Inactivated vaccines do not spread from one bird to others. Consequently, those birds which were not injected or were injected with a sub-dose will not achieve the desirable level of immunity.

- The use of manual syringes is tiring and it could lead to the injection of a fraction of the recommended dose.

- Vaccines improperly injected can lead to tissue reactions and it might lead to problems with growth and uniformity of the flocks affecting negatively the egg production.

- Safety for the vaccination crew is an important issue to be considered. Self-injection of an oil emulsion vaccine is rather painful and, in extreme cases, it can lead to the loss of part of the affected finger.

For all these aforementioned reasons, the poultry industry has been looking for more professional ways to properly inject pullets prior to the onset of egg production and therefore improving the immunity and the overall results of the flocks.

.

Importance of Proper Injection

It is clear to everyone involved in poultry production that a proper injection of an inactivated vaccine is essential to achieve the desirable levels of protection during the production period and, in breeders, to transmit high and uniform levels of MDA to day-old chicks.

However, the detrimental effects of a sub-optimal vaccination procedure are not so obvious to producers. More importantly, it is rather difficult for farmers and animal health managers to evaluate the quality of the administration of inactivated vaccines practiced in their own production facilities. In some cases, they will suspect of misadministration of the killed vaccines when the flocks are affected by diseases.

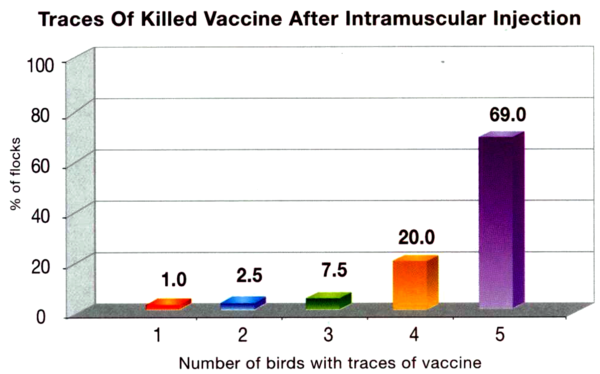

To survey the quality of injection carried out at field conditions, Doucet and Guyony (1997) randomly selected 5 pullets from 1.486 pullet flocks with ages ranging from 18 – 20 weeks and looked for number of pullets with traces of the injection. The results are expressed in the Graphic 1

Graphic 1 Traces of killed vaccine after intramuscular injection

These results reflect very accurately the field situation. Only in 69% of the flocks, traces of the vaccine were found in all 5 necropsied pullets. In other words, 31% or almost ⅓ of all vaccinated flocks were not properly injected. Furthermore, this survey did not show whether the correct amount of vaccine was injected.

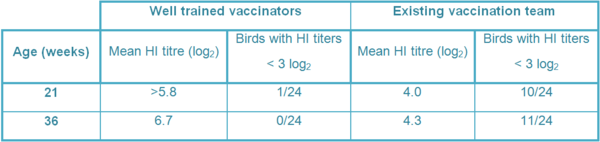

In another interesting trial, the importance of the vaccinators’ skills on the development of flock immunity was evaluated by Van Eck (1997). A pullet flock with 16.5 weeks of age was divided into two parts. One part was vaccinated with EDS vaccine by the existing vaccination crew and the other half received the same vaccine, but injected by well trained people.

The EDS vaccine was used as it is an inactivated product and there is not any live priming that could interfere with the seroconversion. In other words, the humoral immunity would depend exclusively on the injection of the EDS vaccine.

Haemagglutination inhibition (HI) test was carried out at 21 and 36 weeks of age and the results were expressed in Mean HI titre (log2) and Birds with HI titers lower than 3log2. Table 1 summarizes the results:

Table 1 The summarised result of HI test

It is very interesting to notice that a flock vaccinated with the same vaccine and under the same environmental conditions could have such significant differences in the results only because of quality of the injection.

Comparing the HI titres from both groups at 36 weeks of age, it is clear that, when the vaccine was properly injected, the seroconversion was more than 2 logs higher that the group vaccinated by the existing vaccination crew. When the number of birds with HI titers below 3log2 is compared, the differences are even more obvious. For example, at 36 weeks of age, almost 50% of the hens (11 out of 24) of the group vaccinated according to the routine procedures were below the threshold of protection. Alternatively, in the other group, all birds could be considered protected.

These aforementioned trials confirm what the common sense says about the quality of injection. If an inactivated vaccine is not properly injected, the seroconversion will not be as expected.

.

Improving the Quality of Injection

Because of all these aforementioned reasons, producers are looking for solutions to overcome the major shortcomings of the intramuscular injection in the farms and consequently improving the quality of the injection and ultimately the performance of flocks.

The definitive answer to these concerns lies in an innovative equipment: Desvac IMVAC®. This equipment allows precise intra-muscular breast injection of layers and breeders. Moreover, the machine is projected to do single or double injections and can be used for birds from 12 – 19 weeks of age.

The accuracy of the vaccination relies on a specially designed and patented mould with three detection points that must be activated at the same time in order to trigger the injection. It ensures the correct positioning of the birds and guarantees the proper site of injection. Furthermore, each detection sensor is connected with a LED giving direct visual confirmation of the status of the breast position prior to the injection.

An important secondary advantage of this machine is the significantly reduced risk of accidental injection to vaccination personnel. Additionally, it is possible to use the equipment to count the number of birds in the flocks or even to ensure a uniform distribution of the pullets per cage.

The vaccination speed is ranges from of 700 to 1.000 pullets per hour and it depends mainly on the organization of bird presentation. The machine works on compressed air and the two injection lines are individually controlled, allowing thus two vaccines with different adjuvant viscosity or dose to be used.

.

Conclusion

In a competitive industry with narrow margins as poultry production, there is no room for mistakes. Furthermore, the quality of injection is essential to achieve a good immune response and ultimately to improve the overall flock performance. In such an environment, it is unacceptable to continue to inject vaccines knowing that results probably will be disappointing.

Therefore, administering inactivated vaccines with Desvac IMVAC® is the most reliable way to ensure their proper injection and consequently protecting the flocks’ health and the company’s profitability.

If you need to download this article, please do not hesitate to contact us!

Corporate Website

Corporate Website

Africa

Africa

Argentina

Argentina

Asia

Asia

Australia

Australia

Belgium

Belgium

Brazil

Brazil

Bulgaria

Bulgaria

Canada (EN)

Canada (EN)

Chile

Chile

China

China

Colombia

Colombia

Denmark

Denmark

Egypt

Egypt

France

France

Germany

Germany

Greece

Greece

Hungary

Hungary

Indonesia

Indonesia

Italia

Italia

India

India

Japan

Japan

Korea

Korea

Malaysia

Malaysia

Mexico

Mexico

Middle East

Middle East

Netherlands

Netherlands

Peru

Peru

Philippines

Philippines

Poland

Poland

Portugal

Portugal

Romania

Romania

Russia

Russia

South Africa

South Africa

Spain

Spain

Sweden

Sweden

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Kingdom

United Kingdom

USA

USA

Vietnam

Vietnam