...

-->Introduction

+ Incubation time: incubation temperature, age and size of eggs

+ Humidity (air relative humidity) – weight loss

+ Temperature, humidity, ventilation

+ Spread of hatch: impact on chick quality

-->Conclusion

...

INCUBATION AND HATCHING PROCESSES

Main Factors Affecting the Hatchability

By Avian Business Unit – CEVA Santé Animale – Libourne, France

.

INTRODUCTION

Artificial incubation was developed with the main objectives to recreate the temperature and relative humidity close to the natural conditions. By allowing mass production of chicks, artificial incubation has greatly contributed to the rapid expansion of poultry industry.

Image 1 Artificial incubation

Moreover, it has also kept the pace with technical progress. The genetic improvements that have been achieved for the past 30 years have reduced the time required for producing a 2-kilogram chicken by over a factor 2. This progress was accompanied by changes in chick embryology, including particularly the emergence of highly exothermic breeds.

In the meantime, machines have been improved from the first upgraded ovens of the 1960s, when one would simply raise the temperature empirically according to the results found, to the modern incubators that finely regulate temperature, relative humidity and ventilation according to the stage of embryonic development.

In this article, some parameters of the incubation and hatching processes will be revised. All the following information refers to “Gallus” chicks, whose total incubation time is 21 days and which divides into two phases with transfer at 18 days from incubator to hatcher.

^ Top page

.

INCUBATION PARAMETERS

1. Incubation Time: Incubation Temperature, Age and Size of Eggs

Three main factors influence egg total incubation time:

- Incubation temperature: the higher the incubation temperature, the shorter the incubation time. A temperature too high leads to early hatching and smaller chicks; whereas a temperature too low results in hatching delay from 2 to 12 hours depending on temperature, and larger chicks. In both cases, extremes also lead to an increase in embryonic mortality.

- Age of egg: beyond 5 days of storage, each additional day prolongs the incubation time by one hour.

- Size of egg: beyond 50 grams, each 2.5-gram range prolongs the incubation time by half an hour.

Numerous secondary factors also influence incubation time: breed (layer type or meat type chickens), period of the year, number and type of eggs in the incubator, type of incubator used.

There are actually two different thermal phases during incubation:

- The first phase (until 8 days of incubation approximately), when the embryo requires heat in order to develop, is called the endothermic phase. During this first phase, insufficient heating, too slow temperature rise or interruption of the “warm chain” can result in early embryonic deaths and impair the incubation final outcome.

- The second phase (from approximately 8 days of incubation onwards) is when the embryo produces heat which is needed to be dissipated; hence, this is the exothermic phase. Besides, some breeds with high growth potential release more heat than others and it should be taken into account during incubation.

Normally, the incubation temperature is set for each hatchery. Depending on the time desired for chick delivery, the incubation time could be adapted according to the age and size of the eggs.

For example: if 50-gram eggs (young breeders) require 21 days to hatch (504 hours) after a 3-day storage period, 60-gram eggs (older breeders) will require 5 additional hours after an 8-day storage period:

- Size correction: 10 g, i.e. 4 x 30 minutes = 2 hours

- Age correction: 3 days (duration exceeding 5 days), i.e. 3 x 1 hour = 3 hours

^ Top page

.

2. Humidity (Air Relative Humidity) – Weight Loss

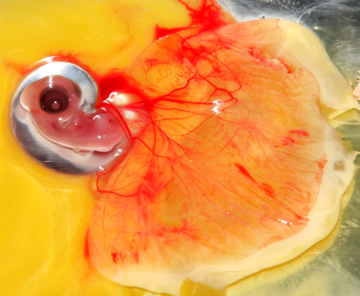

Image 2 Chick embryology

This is one of the most important parameters of incubation. Water vapor escapes through shell pores, a phenomenon influenced by the number and size of pores and the ambient air relative humidity. The water loss that the egg undergoes during normal incubation reaches 12% to 14% of its weight approximately. This can be easily demonstrated by the constant enlargement of the air cell.

Note: to this weight loss occurring during incubation one must add the weight loss occurring in the hatcher and while the egg is waiting to be delivered. It is estimated that the chick’s weight represents approximately 68% (62-76%) of the egg. Consequently, a 60-gram egg will yield a 41-gram chick on average: 8 g will be lost during incubation (humidity) and 11 g after hatching (humidity, egg shells and shell membranes).

The relative humidity level during incubation varies according to numerous parameters: breed, age of egg, age of flock and weight of egg, washing prior to incubation and the type of machine.

However, it is important to keep in mind that excessive humidity causes pipping difficulties as the air cell is not sufficiently developed and therefore an increase in the percentage of pipped but unhatched eggs. As fluid resorption is poorer, chicks are larger, even swollen, and weaker. Finally, the risk of omphalitis is increased.

Alternatively, insufficient humidity causes dehydration, leading to smaller chicks with sparse down. Shell membranes stick to the embryo and hatching difficulties can also be observed.

^ Top page

.

3. Ventilation

As any living being, the egg breathes, taking in oxygen (7 grams in 21 days) and giving off carbon dioxide (9 grams). The fresh air drawn from the incubation room therefore provides the eggs with the oxygen and humidity that they need, and takes away the carbon dioxide and excessive heat that they produce. Ventilation is a major factor at the end of the cycle.

These gas exchanges explain why storage time and age of breeders influence incubation time. Indeed, at the time of laying, the egg is an acid environment as it has taken up carbon dioxide while moving on through the reproductive tract. Then, the oxygen present in the air gradually takes over from carbon dioxide and the internal pH increases. These conditions undermine the formation of the embryo’s nutritive fluid and slow down embryonic development.

In incubators, the normal level is 21% for oxygen and approximately 0.4% for carbon dioxide (0.2% during the first phase and 0.5% at the time of transfer).

^ Top page

.

4. Egg Position and Turning

Each hatching egg should be positioned with the small end down so that the embryo is given a correct orientation. Inside the incubator, those eggs should constantly be at a 45o angle. Finally, they should be turned regularly, every other hour or even every hour, in order to prevent the embryo from sticking to the shell and adopting an abnormal position. This operation also allows heat to be uniformly distributed among the eggs.

Egg turning is particularly crucial during the first 8 days, when an error in machine programming can lead to 70% death among embryos. After the first 15 days, egg turning becomes somewhat more optional.

^ Top page

.

TRANSFER AND HATCHING

On the 18th day of incubation, the hatching eggs are transferred from setter trolleys to hatcher baskets and placed in a new room and new machine: the hatcher. Hatching occurs within 3 days following the transfer.

A common rule is to open the hatcher when 5-10% of the chicks are still wet behind their neck. Chicks are held in a room where a temperature of 24°C or more and a relative humidity of 50% have to be ensured. Dehydration must be prevented.

1. Transfer on Hatcher Baskets

Unlike setting trays, hatcher baskets are not equipped with egg racks: the eggs are placed on their side, which makes it easier for the chick to move when pipping. Trays, in particular, must be totally dry to prevent eggs from cooling at the time of water evaporation in the hatcher.

In some circumstance, it may be useful to spread out a sheet of paper on the bottom of hatching trays (unless this hinders air circulation) in order to make tray washing easier and improve chick comfort (lower number of chicks with sprawling legs due to slippery trays).

This transfer operation must be done as quickly as possible (2 to 4 hours) in a temperature-controlled room so as to prevent egg cooling and hatching delay. Furthermore, the baskets should be handled carefully as egg shells (the calcium of which has been absorbed by chicks) and embryos are fragile. Shaking the eggs at this stage may cause breakage or hemorrhages.

^ Top page

.

2. Egg Candling

Candling is performed before transferring the eggs on hatching trays and responds to various economic objectives:

- Checking fertility and evaluating the number of chicks to be produced,

- Optimizing machine operation and labor on the day of hatching,

- Enhancing machine correct functioning and achieving good quality chicks,

- Sparing vaccine by culling clear eggs prior to “in- ovo” vaccination.

This candling test also has a sanitary objective as it enables culling of clear eggs (unfertilized, dead and rotten eggs), which are a potential source of contamination to the other eggs.

If the percentage of clear eggs is low (up to 5%, checked by partial candling), candling may possibly be left undone, which enables savings on labor and rapid transfer with no egg handling. However, there is a tendency today for total candling, which is automatically performed while transfer is being operated.

The number of eggs per tray can be adjusted, without necessarily completely filling the trays. It is reasonable to fill the trays to 90% of their capacity.

Note: In some circumstances, performing early candling (between 7 and 12 days of incubation) is also recommended to determine flock fertility and rapidly remedy in case of any fertility problem.

^ Top page

.

3. Temperature, Humidity, Ventilation

These three factors remain important in this phase.

- Temperature: it is slightly lower than in the incubator. Be careful of machine cooling systems that are not always efficient enough regarding overheating risks. The ideal temperature is 37.1°C.

- Humidity: the humidity needed for hatching must not be produced by the chicks themselves, but by the hatcher. It is too often heard that one only needs to let things be for things to go well; however, if water is supplied by the chicks, there is a risk that they weaken; hence leading to a decrease in the hatching and viability percentage. Humidity is crucial at the beginning of hatching to ensure suitable softness of shell membranes. At the end of hatching, it is reduced to enable chicks to dry off.

- Ventilation: The supply of fresh air must be sufficient to prevent a lack of oxygen and choking. Ventilation must be minimal at the beginning of hatching in order to help initiate pulmonary respiration (which is prompted by a high level of carbon dioxide), and later must be increased until becoming maximal at the end of hatching.

^ Top page

.

4. Spread of Hatch: Impact on Chick Quality

The spread of hatch (or hatch window) is the time interval during which egg hatching occurs. Ideally, it should last 24 hours, which means that the first pipped eggs must appear 24 hours before the scheduled opening of the hatcher.

In practice, it often lasts longer and a great number of chicks may hatch before the last day. In some cases, pipped eggs can even be seen at the time of transfer from the incubator to the hatcher, which makes a hatching window of more than 72 hours. Obviously, in that case, incubation parameters should be reconsidered, as well as preheating and storage parameters. The temperature, which is probably distributed heterogeneously, must be revised thoroughly.

Basically, depending on the spread of the hatch, there are two different consequences on chick quality:

- Too early hatchingresults in dehydrated and tired chicks when exiting the hatcher.

- Too late hatchingleads to weak and wet chicks with frequent omphalitis problems.

Eventually, this indicates a poor-quality and heterogeneous batch with an increase in mortality at hatching.

^ Top page

.

CONCLUSION

The main parameters contributing to successful incubation have to be constantly monitored and eventually adjusted in those cases where abnormal results have been achieved. However, it is important to mention that the figures mentioned here above are only indicative and they must serve only as a guideline.

Should you need additional information about incubation and hatching procedures, the equipment supplier will be able to give detailed information about the proper settings for your equipments.

In summary, in the hatchery, losses are mainly due to clear or infertile eggs, embryonic mortalities, mortality at pipping shortly after hatching, egg-sorting operations after hatching and “downgrading” of poor-quality chicks.

^ Top page

If you need to download this article, please do not hesitate to contact us!

Corporate Website

Corporate Website

Africa

Africa

Argentina

Argentina

Asia

Asia

Australia

Australia

Belgium

Belgium

Brazil

Brazil

Bulgaria

Bulgaria

Canada (EN)

Canada (EN)

Chile

Chile

China

China

Colombia

Colombia

Denmark

Denmark

Egypt

Egypt

France

France

Germany

Germany

Greece

Greece

Hungary

Hungary

Indonesia

Indonesia

Italia

Italia

India

India

Japan

Japan

Korea

Korea

Malaysia

Malaysia

Mexico

Mexico

Middle East

Middle East

Netherlands

Netherlands

Peru

Peru

Philippines

Philippines

Poland

Poland

Portugal

Portugal

Romania

Romania

Russia

Russia

South Africa

South Africa

Spain

Spain

Sweden

Sweden

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Kingdom

United Kingdom

USA

USA

Vietnam

Vietnam