...

--> Introduction

-->Droplet size and post-vaccination reactions

--> Conclusions

...

SPRAY VACCINATION: WHAT HAPPENSDURING AND AFTER THIS PROCEDURE

By Roberto SOARES(1) and Marcelo PANIAGO(2),

(1) DVM, MSc, ACPV. International Product Manager – Poultry, CEVA Santé Animale, La Ballastiere, BP 126, 33501, Libourne Cedex, France

(2) DVM, MSc, MBA, Regional Market Manager – Poultry, CEVA Animal Health Asia – Petaling Jaya, Selangor, Malaysia

.

INTRODUCTION

Spray vaccination can be defined as the method for administration of the live vaccines (dissolved in water), in the form of droplets, through the air to the birds’ target cells (Jorna, A.). It is considered the most efficient route for massive vaccination against ND and IB as it triggers local immunity in the respiratory tract. Moreover, as the respiratory tract is the main site of entry of NDV and IBV, local immediate immune mechanisms therefore form a first line of defence against these infections. Besides that, spray vaccination also induces humoral immune response.

This method of vaccination can be done either in the hatchery with cabinet sprayers or at the farms with different kinds of equipments and it allows the vaccination of a large number of birds in a short period of time with low cost. Nevertheless, it is not always synonymous of efficacy as it can lead to vaccination failures (uneven uptake) and/or development of Post-Vaccination Reactions (PVR) if it is not properly managed.

In order to reach the desirable results with the spray process, it is important to consider some key points as the formation of the droplets and the target to be reached (respiratory or digestive tract). Therefore, the objective of this article is to describe the events that happen during the spray vaccination and moments after this procedure, in order to better understand it and consequently improve its results.

^ Top page

.

DROPLETS FORMATION

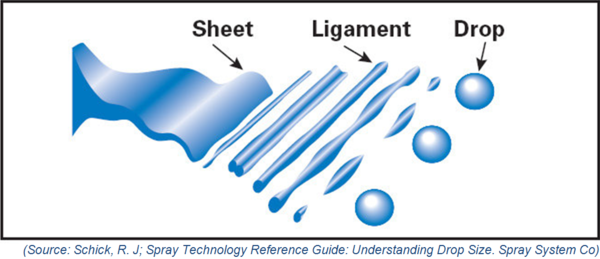

The spraying process consists of forcing the vaccine solution through hydraulic nozzles using determined pressure, which provides the energy that breaks a stream of water into droplets. The size of the droplets produced by this process is influenced by pressure, type of nozzle and environment conditions. These droplets can be classified, according to their size at the point of production (after leaving the nozzles), as atomization or aerosol (<50 μm), fine spray (50 – 100 μm) or coarse spray (100 – 150 μm).

Figure 1 The droplet size in spray technology

^ Top page

.

a. Pressure

When the vaccine solution emerges from the nozzle, it is in a form of a thin sheet and the droplets will be formed on its edge. As the pressure changes, this sheet can be either thicker (lower pressure) or thinner (higher pressure) and it will generate larger or smaller droplets, respectively.

This process can be easily observed when a regular sprayer with manual pumping system and no pressure regulator is used. In this case, at the beginning of vaccination, when the pressure is high, the droplets are extremely small. However, as the tank pressure reduces, the droplets become bigger.

Knowing this concept, it is easy to understand the importance of keeping a constant pressure in the sprayers in order to achieve as homogeneous droplets size as possible throughout the vaccination process.

Another practical implication of the pressure affecting the droplet formation can be observed in the hatcheries. Cabinet sprayers with more than one nozzle may have pressure problems when one of the nozzles is partially or totally obstructed as this situation not only causes an irregular spray pattern but also may increase the pressure on the other nozzle(s) generating smaller droplets.

^ Top page

.

b. Nozzle

Figure 2 The type of nozzle in the equipment

The particle size is also regulated by the type of nozzle used in the equipment. Keeping the same pressure, different types of nozzles produce different sizes of droplets, varying from atomization to coarse spray. Thus, specific nozzle, which generates coarse spray, is recommended for primer vaccination. Alternatively, for subsequent boosters in the farms, where smaller droplets could be required, different type of nozzle should be used.

Usually, equipment suppliers provide the average droplet size produced by a given type of nozzle under certain pressure. However, it is necessary to keep in mind that the nozzle produces in fact a wide range of droplets, varying from very small droplets to large ones. It means that, even using coarse spray, part of the droplets will be smaller than the average and they will go deeper into the respiratory system.

^ Top page

.

c. Environment conditions

Figure 3 Spray vaccination in the farm

The droplet size can be measured either at the production site (after leaving the nozzles) or at the impact side (nostril of the birds). Environment factors, such as high temperature and/or low relative humidity, cause variation in the droplets size between these two points (production / impact) due dehydration. This is not a big concern for cabinet sprayers in the hatchery, but certainly it is something to be considered during spray vaccination in the farms.

The size of the droplet is also affected by the distance between the nozzle and the birds. Consequently, it is necessary to keep a constant distance from the birds during the whole procedure of spray vaccination by avoiding moving the spray lance up and down or even by trying to reach birds faraway from the nozzles.

^ Top page

.

THE TARGETED CELLS

The objective of the spray vaccination against respiratory diseases is to deliver a live antigen on the mucous membrane of upper respiratory tract (nostrils, turbinate, sinuses and trachea) and in the eyes. Even though it will not be discussed in this article, spray vaccination can also be used for delivering vaccines against coccidiosis and in this case the target cells are different.

a. Inhalation

After entering the nasal cavity, the inhaled air carrying the vaccine droplets will start to rotate due to the complex turbinate system, throwing the largest droplets (>3μm) against the wall. At this moment, most of virus particles will be able to attach and infect the nasal epithelial cells. However, some other particles will be trapped in the mucous layer and quickly moved down to the pharynx by ciliar movement and thus they will be swallowed and excreted in the faeces.

The larger droplets which are able to pass through this turbinated area can find physical barriers in the pharynx and trachea (muco-ciliar system) and will sediment along this area. Alternatively, droplets smaller than 3 μm at the impact side can pass through all this filtration system and they will be deposited in the lower respiratory tract (lung and air sacs).

^ Top page

.

b. Mucous absorption through the eyes

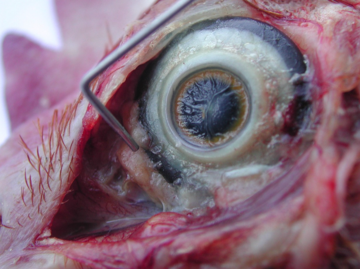

Figure 4 Examine the mucous after the realization of spray vaccination

The droplets that reach the eye deliver the vaccinal virus which will replicate in the conjunctive cells and thus stimulating the Harderian gland. After stimulated, this secondary lymphoid tissue will be responsible for local protection through activated T and B cells and antibodies production.

Vaccinal viruses will also be drained into the naso-lacrimal duct, where they will attach and replicate. This naso-lacrimal duct is lined by the same epithelial cells found in the nostril, therefore the mechanism of clearance is exactly the same as aforementioned. Viruses that did not attach to the wall are carried into the mouth by the mucous and ciliar movement and consequently swallowed.

^ Top page

.

DROPLET SIZE AND POST-VACCINATION REACTIONS

As it was aforementioned, a nozzle with a pre-set pressure may generate a range of different droplet sizes. Moreover, the site of deposition of these inhaled droplets in the respiratory tract of the chickens is variable and it is directly related to the size of the droplets. Therefore, it is import to take into consideration that, even using a well adjusted coarse spray device, a few small droplets (< 3μm at impact site) may be formed and end up in the lungs and air sacs.

Whenever non-pathogenic or mild strains are used, few droplets that may reach deeper parts of respiratory tract will cause none or very mild inflammatory response. Alternatively, a few droplets of a more virulent strain into the lung and/or into the air sacs are enough to cause severe respiratory reaction and consequently reduction in the growth of the birds or even affecting egg production in adult chickens.

In both situations, the involvement of other microrganisms, such as Mycoplasma gallisepticum and Escherichia coli, may exacerbate the reaction. Furthermore, it is important to note that PVR may also be aggravated whenever vaccination is carried out in situations where birds are panting (hot environment, for example). In these circumstances, droplets may bypass the nose filtration system and going directly into the trachea and lung.

^ Top page

.

CONCLUSIONS

The success of the vaccination depends, among others, on the vaccine itself and the method used to deliver it to the birds. For spray vaccination, both in the hatcheries or in the farms, the success depends directly on the vaccine strain and the equipment utilized.

Therefore, for vaccination in the hatcheries, only high quality vaccines with virus strains appropriated for day-old administration and cabinet sprayers which are able to provide uniform droplet size and excellent coverage of the crate should be used. Furthermore, the recommendations of the supplier concerning to installation, use and preventive maintenance of the equipment should be strictly followed.

At last but not at least, the close follow-up of the vaccination routine is essential to identify any problem as early as possible in order to correct it and keep achieving the goals of the immunization of birds against respiratory diseases.

^ Top page

If you need to download this article, please do not hesitate to contact us!

Corporate Website

Corporate Website

Africa

Africa

Argentina

Argentina

Asia

Asia

Australia

Australia

Belgium

Belgium

Brazil

Brazil

Bulgaria

Bulgaria

Canada (EN)

Canada (EN)

Chile

Chile

China

China

Colombia

Colombia

Denmark

Denmark

Egypt

Egypt

France

France

Germany

Germany

Greece

Greece

Hungary

Hungary

Indonesia

Indonesia

Italia

Italia

India

India

Japan

Japan

Korea

Korea

Malaysia

Malaysia

Mexico

Mexico

Middle East

Middle East

Netherlands

Netherlands

Peru

Peru

Philippines

Philippines

Poland

Poland

Portugal

Portugal

Romania

Romania

Russia

Russia

South Africa

South Africa

Spain

Spain

Sweden

Sweden

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Kingdom

United Kingdom

USA

USA

Vietnam

Vietnam