...

--> Introduction

--> Droplet size and type of vaccine used

--> Maintenance of sprayer equipment

--> Conclusion

...

SPRAY VACCINATION IN THE HATCHERIES

- Key Points to Achieve Proper Immunization of the Day-old Chicks -

By Marcelo PANIAGO, DVM, MSc, MBA, Regional Market Manager for Poultry

Ceva Animal Health Asia Pacific – Petaling Jaya, Selangor, Malaysia

.

INTRODUCTION

Over the years, poultry producers have shown a preference for vaccinating their chicks in the hatchery. Some of the reasons include the opportunity of massive vaccination as all day-old chicks (DOC) are confined in a small space, the availability of highly automatic equipments for hatchery, the awareness that this is the best way to face early challenge in the farms and to have more consistent and standardized results than vaccinating in different farms.

Spray vaccination can be defined as the method for administration of the live vaccines (dissolved in water), in the form of droplets, through the air to the birds’ target cells (Jorna, A., personal communication). It is considered the most efficient route for massive vaccination against ND and IB as it triggers local immunity in the respiratory tract. Moreover, as the respiratory tract is the main site of entry of NDV and IBV, local immediate immune mechanisms therefore form a first line of defense against these infections. Besides that, spray vaccination also induces humoral immune response.

Furthermore, spray vaccination at hatcheries as compared to spray on-farm has several advantages as lower labor cost, fewer birds missed, less post vaccination reaction (PVR), easier to monitor droplet size and distribution, more consistent administration and fewer environment interfering factors.

Whatever the reason for adopting the vaccination at hatcheries, it should be considered that it also has its own challenges and the achievement of good results will depend on the correct administration of the vaccine.

^ Top page

.

TYPES OF SPRAYERS

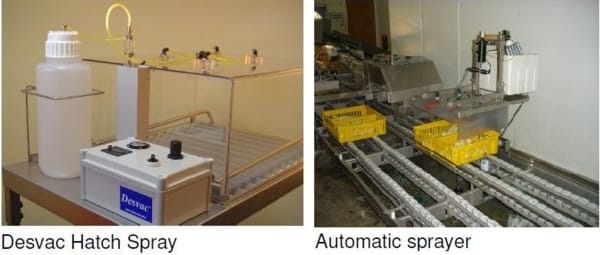

Basically, there are two different systems for spray vaccination at hatcheries, manual or automatic.

- In the first system, the crates are manually introduced into the acrylic chamber and then the spray nozzles are activated. After vaccination, the chick’s boxes are manually removed from the chamber.

- In the automatic system, the sprayer is installed on the conveyer belt and the spray is activated when the crates pass through the equipment.

The manual cabinet sprayer is the most used type worldwide. The automatic sprayer system is more suitable for the big hatcheries with high level of automation or in those situations where labor cost is a critical issue.

^ Top page

.

SPRAY VACCINATION

No matter which equipment is installed in the hatchery, recommendations related to the vaccination are quite similar. The sprayer is regulated to work with a fixed air pressure and the key point is to ensure the quality of this compressed air which must be clean and containing as little humidity as possible.

Before the vaccination, it is important to evaluate the volume sprayed per crate and distribution of the droplet inside of them. The volume sprayed can be assessed either by using a calibrated jug before starting the vaccination or later on by comparing the number of vaccinated crates with the number of vaccine’s doses prepared. The recommended volume is around 15 ml per crate.

A homogeneous distribution of droplets inside of the crates is crucial to achieve proper immunization of the vaccinated birds and the assessment of this distribution can be done in one of the following ways:

- Whenever cardboard boxes are used, just spray one empty box before the onset of vaccination and evaluate the distribution of droplets in its bottom. With plastic crate, it is possible to cover its bottom with absorbent paper to check the distribution of droplets on it.

- By using a dye mixed to the vaccine solution, it is possible to evaluate the coverage of head and body of the day-old chicks. At least 80-90% should be dyed.

- The other possibility is to use “water sensitive paper” to evaluate the distribution and also the homogeneity of droplet size.

Another decisive step is the preparation of the vaccines. Only fresh and clean distilled water or even de-ionized water must be used for this dilution. Be sure the water does not contain any residue of chlorine, disinfectants or metals and do not clean the parts of the sprayer which will be in contact with the vaccine using disinfectants. It can impair or even ruin the result of the vaccination.

The spray vaccination itself should be carried out only by well trained personnel. Using cabinet sprayers, only around 30.000 – 36.000 DOC per hour should be vaccinated. Going much above this limit can cause problems in the quality of process.

^ Top page

.

DROPLET SIZE AND TYPE OF VACCINE USED

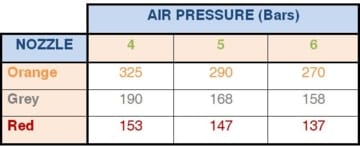

The droplet size is an extremely important issue to be considered in the spray vaccination. Usually, cabinet sprayers are used for coarse spray with a droplet size around 150 μm. This size is regulated by the type of the nozzle and the pressure in the system (Table 1).

Table 1. Droplet Size (μm) accordinly to the Nozzle Type and Air Pressure

These recommendations are valid for spray of 15 ml with 4 nozzles on Desvac Hatch Spray. If you have a different supplier, check the combination of nozzle and air pressure which gives the droplet size it is required for this vaccination.

As it was aforementioned, spray vaccination is considered the most efficient route for massive vaccination against respiratory diseases. However, in some circumstances, post-vaccinal reactions (PVR) can be seen after this procedure. Two situations are particularly important and must be considered. The use of strains with high ICPI (Intracerebral Pathogenic Index) against ND, like LaSota strain, and flocks contaminated with Mycoplasma gallisepticum.

The use of respiratory strains with high ICPI tends to lead to the reactions that are unacceptable for the modern poultry industry standards. Then, for spray vaccination in the hatcheries, it is highly recommended to use apathogenic enteric strains against ND which are fully protective and can be safely used even in flocks contaminated with M. gallisepticum.

^ Top page

.

MAINTENANCE OF SPRAYER EQUIPMENT

Spray vaccination depends essentially of the well functioning of the equipments involved. So, it is needless to say that, to ensure good results of the vaccination, the cabinet sprayers and the air compressor must be routinely maintained.

As part of the maintenance work, some spare parts, as O-rings, springs and tubes, must be kept in the hatcheries. Furthermore, it is strongly advised to follow strictly the recommendations of the equipment supplier. It will ensure a good functioning of the equipment.

^ Top page

.

CONCLUSION

The success of the vaccination depends, among others, on the vaccine itself and the method used to deliver it to the birds. For spray vaccination in the hatcheries, the success depends directly on the vaccine and the equipment utilized. Because of these reasons, only high quality vaccines with virus strains appropriated for day-old administration and cabinet sprayers which are able to provide uniform droplet size and excellent coverage of the crate should be used. Furthermore, the recommendations of the supplier concerning to installation, use and preventive maintenance of the equipment should be strictly followed.

At last but not at least, the close follow-up of the vaccination routine is essential to identify any problem as early as possible in order to correct it and keep achieving the goals of the immunization of DOC against respiratory diseases.

.

ACKNOWLEDGEMENT

The author would like to acknowledge the valuable advices given by Mr Anno Jorna, from Desvac (www.desvac.com) during the elaboration of this paper.

If you need to download this article, please do not hesitate to contact us!

Corporate Website

Corporate Website

Africa

Africa

Argentina

Argentina

Asia

Asia

Australia

Australia

Belgium

Belgium

Brazil

Brazil

Bulgaria

Bulgaria

Canada (EN)

Canada (EN)

Chile

Chile

China

China

Colombia

Colombia

Denmark

Denmark

Egypt

Egypt

France

France

Germany

Germany

Greece

Greece

Hungary

Hungary

Indonesia

Indonesia

Italia

Italia

India

India

Japan

Japan

Korea

Korea

Malaysia

Malaysia

Mexico

Mexico

Middle East

Middle East

Netherlands

Netherlands

Peru

Peru

Philippines

Philippines

Poland

Poland

Portugal

Portugal

Romania

Romania

Russia

Russia

South Africa

South Africa

Spain

Spain

Sweden

Sweden

Thailand

Thailand

Tunisia

Tunisia

Turkey

Turkey

Ukraine

Ukraine

United Kingdom

United Kingdom

USA

USA

Vietnam

Vietnam